Saw tooth effect happens when the emulsion cannot bridge the gap between mesh openings especially in diagonal directions from corner to corner. Saw tooth effect - Poorly coated screens can be the direct cause of this all to common result.

Be careful to expose the emulsion just enough to thoroughly cure it. Over exposure can also cause undercutting. This can be minimized by making sure your film positive comes in contact with the emulsion on the same side that the image was applied to the clear film base. This is light scatter caused by light passing through the clear film base on its way to the emulsion. Undercutting or loss of detail - White mesh may produce this problem by halation. Make sure your emulsion is well mixed when using two part diazo or dual cure emulsions. Another cause of this may be incompletely dissolved sensitizers. This should be kept in mind if you work quickly and especially in high humidity regions. That is to say that if there are still high amounts of humidity in the emulsion, it can affect adhesion. But it is a problem that may occur if the screen is exposed before it is completely dry. Poor emulsion adhesion - This too is can be caused by improper mesh preparation. Also, after mixing the emulsion, it is recommended to allow it to sit for some time so that all of the air bubbles introduced during mixing may settle. It is best to use a slow pass when coating the mesh with emulsion. But, pinholes may also be produced by air bubbles being left in the screen due to rapid coating passes.

Pinholes and/or air bubbles - Pinholes are often caused by dust or debris on the screen or in the emulsion during coating. Poorly mixed sensitizers and photopolymer emulsions that have been sitting for long periods of time and not mixed before use may also cause these symptoms.

These problems may be easily avoided with proper mesh prep. Any dirt or debris will cause emulsion problems. It is very important to remove all of the grease and dust. Check out this briefing on the most common issues with direct emulsions.įormation of fish-eyes, crescents, half moons - This could be the result of inefficient mesh prep procedures. Some of the most common direct emulsion problems can be directly related to screen making.

SCREEN PRINT PHOTO EMULSION SCREEN PRINTING HOW TO

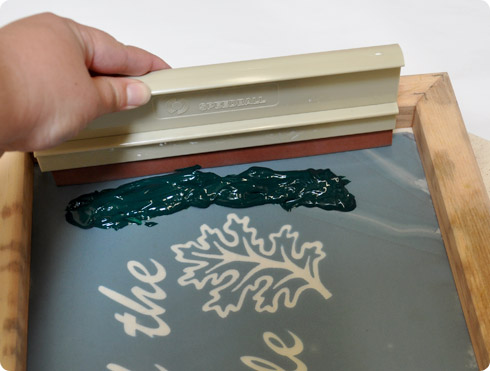

And of course it would then be important to understand how to solve them as well. When coating your own screens with direct liquid emulsions, it is necessary to easily identify the cause of common problems. Trouble Shooting Tips For Direct Emulsions Store unused stencils in a cool, dark place (like your refrigerator) and use within 6 months of purchase for best results.Learn How To Screen Print With Catspit Productions, LLC EZScreen HiDef has a higher thread count, therefore, y ou can achieve superb details with HiDef screen printing stencils and the mesh transferred to the paint is less visible than Standard on hard surfaces.īurn EZScreen stencils in direct sunlight, or use one of our artificial light kits if sun is not available. Typically, used for hard surfaces such as glass, plastic, and metal. Fast & Easy DIY Screen Printing Stencils!ĮZScreen Standard Emulsion Stencils are typically used for fabric such as t-shirts, sweatshirts, tote bags and other porous surfaces like ceramic, wood, cardboard, and paper. Regular sheets are easier to clean after exposure to light source, easier to use when applying paint, and is more suited for multiple printing. EZScreen Standard stencils are appropriate for most projects and can achieve incredible details.ĮZScreen HiDef Emulsion Stencils are intended for artwork with small details, fine lines, or halftones.

0 kommentar(er)

0 kommentar(er)